Understanding PREN: A Key Metric for Corrosion Resistance

Pitting Resistance Equivalent Number (PREN) is a critical metric used in materials science to evaluate the corrosion resistance of stainless steels and nickel-based alloys, particularly in harsh environments like seawater or chemical processing plants. PREN provides a numerical value that helps engineers and metallurgists predict how well an alloy will resist pitting corrosion – a localised form of corrosion that creates small pits or holes on a material’s surface.

In industries such as oil and gas, marine engineering, and chemical processing, selecting materials with high corrosion resistance is essential to ensure durability and safety. PREN simplifies this process by offering a standardised way to compare alloys like Ferralium 255 (a super duplex stainless steel) and Alloy 625 (a nickel-chromium alloy).

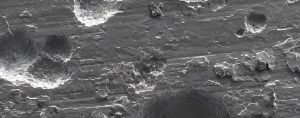

Pitting corrosion in metals is caused by localised breakdown of the protective oxide layer, primarily due to chloride ions in environments like seawater, which attack weak points such as defects or scratches. Factors like high temperatures, acidic conditions, oxygen depletion, or galvanic effects between dissimilar metals accelerate this process, creating small pits that can lead to rapid material failure.

What is PREN and How is it Calculated?

PREN is calculated using a formula that accounts for the key alloying elements contributing to corrosion resistance: chromium (Cr), molybdenum (Mo), and nitrogen (N). These elements enhance an alloy’s ability to form a protective passive layer that resists pitting in aggressive environments, such as those containing chlorides.

The most common PREN formula is:

PREN = %Cr + 3.3 × %Mo + 16 × %N

Chromium (Cr): Enhances the formation of a passive oxide layer that protects the metal.

Molybdenum (Mo): Improves resistance to pitting and crevice corrosion, especially in chloride-rich environments.

Nitrogen (N): Stabilizes the passive layer and enhances pitting resistance, particularly in stainless steels.

Some variations of the formula may include tungsten (W), with a modified version like PREN = %Cr + 3.3 × (%Mo + 0.5 × %W) + 16 × %N, but the simpler version is more widely used.

The higher the PREN value, the better the alloy’s resistance to pitting corrosion. For example:

Ferralium 255 (a super duplex stainless steel) typically has a PREN around 40, thanks to its high chromium (~25%), molybdenum (~3.5%), and nitrogen (~0.25%) content.

Alloy 625 (a nickel-based alloy) boasts a PREN often exceeding 45, driven by its high molybdenum (~9%) and chromium (~22%) content.

Why PREN Matters

PREN is a valuable tool because it allows engineers to select materials suited for specific environments. For instance:

In offshore oil and gas platforms, where equipment is exposed to seawater, alloys with a PREN above 40 are often preferred to withstand chloride-induced pitting.

In chemical processing, where acids and salts are prevalent, high-PREN alloys like Alloy 625 ensure longevity and reliability.

In marine applications, super duplex alloys like Ferralium 255 balance high strength with excellent corrosion resistance, making them ideal for components like propeller shafts.

However, PREN is not the sole determinant of corrosion performance. Factors like temperature, surface finish, and the presence of other corrosive agents can influence real-world outcomes. Still, PREN serves as a reliable starting point for material selection.

Comparing Ferralium 255 and Alloy 625

To illustrate PREN’s practical use, let’s compare two high-performance alloys:

Ferralium 255: A super duplex stainless steel with a PREN of ~40. Its balanced microstructure (austenite and ferrite) provides excellent strength and corrosion resistance, making it ideal for marine and oil and gas applications. Its nitrogen content enhances its PREN, offering robust protection against pitting in chloride environments.

Alloy 625: A nickel-based alloy with a PREN often exceeding 45. Its high molybdenum and chromium content make it exceptionally resistant to pitting and crevice corrosion, even in extreme conditions like acidic or high-temperature environments.

While Alloy 625 typically has a higher PREN, Ferralium 255 may be preferred in applications requiring a balance of cost, strength, and corrosion resistance. The choice depends on the specific demands of the project, such as budget, mechanical requirements, and environmental conditions.

Limitations of PREN

While PREN is a powerful tool, it has limitations:

Composition Variability: PREN calculations assume uniform alloy composition, but actual material properties can vary due to manufacturing differences.

Environmental Factors: PREN doesn’t account for temperature, pH, or other corrosive agents that can affect performance.

Crevice Corrosion: PREN focuses on pitting resistance, but crevice corrosion (occurring in tight spaces) may require additional considerations.

Engineers and Specifiers should use PREN alongside other data, such as corrosion testing and field experience, to make informed decisions.

Conclusion

PREN is an essential metric for evaluating the pitting corrosion resistance of alloys like Ferralium 255 and Alloy 625. By quantifying the contributions of chromium, molybdenum, and nitrogen, PREN helps engineers select materials that can withstand harsh environments, ensuring safety and longevity in critical applications. While not a complete picture of corrosion performance, PREN is a vital tool in the materials science toolkit, guiding the design of durable, high-performance systems.

For professionals in industries like oil and gas, marine engineering, or chemical processing, understanding PREN can make the difference in choosing the right alloy for the job. Whether it’s the robust Ferralium 255 or the high-performing Alloy 625, PREN provides a clear, data-driven way to compare and select materials.

Ready to Choose the Right Alloy for Your Project?

At Langley Alloys, we specialise in high-performance alloys like Ferralium 255 and Alloy 625, designed to meet the demands of challenging environments. Contact our expert team today to discuss your material needs and find the perfect solution for your application.

USA Sales: Email us at [email protected] or call +001 (281) 819 5588

UK Sales: Email us at [email protected] or call +44 (0)1782 610250

Let us help you select the ideal alloy to ensure durability and performance in your next project!